Semiconductor Manufacturing and Applications (High Purity & Ultra High Purity)

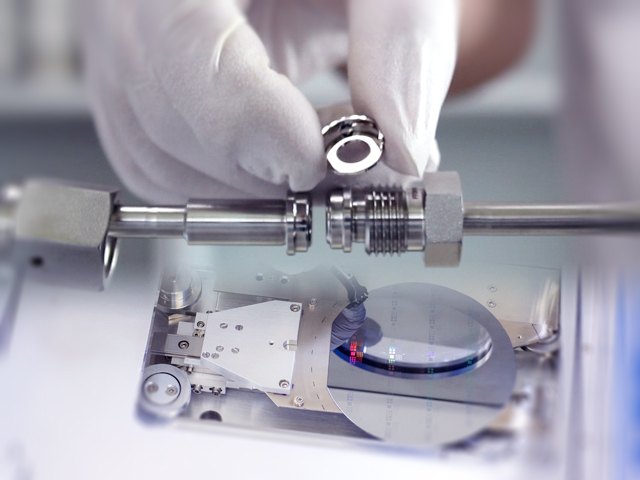

The increasing demands for digitalization and intellectualization have been accelerating the development of the semiconductor industry. In the semiconductor process, valves and fittings are the extremly common and critical components and are widely used in the entire semiconductor manufacturing system --- both in core equipment such as lithography, PVD, CVD, etching machines, and in the wafer fabrication process as well as in piping systems of semiconductor facility.

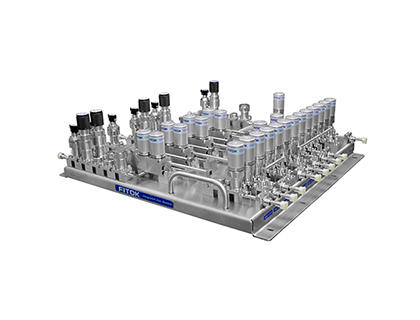

As a global leading supplier of valves and fittings, FITOK can provide one-stop solutions for fluid systems in the semiconductor industry, from ultra high purity components such as valves, fittings and tubing to integrated systems, and from system design to installation site service. By strictly controlling the entire production process from raw material selection to processing, cleaning, welding, assembling and testing, FITOK can provide the semiconductor industry with ultra clean, ultra reliable and corrosion resistant valves, fittings.

Product Features

Process cleanliness is one of the top concerns in the semiconductor industry, and the material purity of fluid system components is critical to achieving the required process cleanliness.

FITOK has customized 316 SS, 316L SS VAR as the valve body material meeting SEMI F20 standard for semiconductor industry applications. As a commonly used material for high purity (HP) and ultra high purity (UHP) products, AISI 316L (UNS S3160) stainless steel has excellent corrosion and oxidation resistance. 316L VAR is refined in a special way to reduce non-metallic inclusions and further enhance the material purity.

Cobalt Alloy

FITOK adopts cobalt alloy complying with AMS 5876 standard or Hastelloy complying with ASTM B575 standard as diaphragm material to achieve high corrosion resistance and excellent durability.

316L VAR

1.Electropolishing

The internal surface of ultra high purity products for the semiconductor industry is electropolished to improve the smoothness of the flow path and to form a chromium-rich layer on the metal surface to improve corrosion resistance, and the electropolished products are passivated to remove free iron ions. After electropolishing, the following testing standards can be achieved:

| Test Item | Test Standard | |

| Oxide layer thickness | SEMI F72 | |

| Surface defect analysis | max. defect counts per area within 5 sample areas | SEMI F73 |

| Cr/Fe | SEMI F60 | |

| CrO/FeO | ||

| Surface roughness (Ra) | SEMI F37 | |

2.Cleaning

Ultra high purity products for the semiconductor industry are rinsed with ultrasonic DI water in the NEBB-certified ISO 5 cleanroom and dried in an enclosed oven. The technical specifications of the DI water comply with SEMI E49 standard.

3.Welding, Assembly, Testing and Packaging

Cleaned products are welded, assembled, tested, inspected and packaged in the NEBB-certified ISO 4 cleanroom. Products are subject to helium leak test as required by SEMI F1 and product packaging complies with SEMI E49 standard. Products are end-capped and double bagged with inner vacuum-sealed clean polyethylene bag and outer polyethylene bag.

FITOK Products for Semiconductor Applications

FITOK supplies a full range of high purity and ultra high purity products, from metal gasket face seal fittings and weld fittings to a variety of valves such as diaphragm valves, bellows-sealed valves, pressure regulators, check valves, etc., as well as electropolished (EP) tubing, gas control equipment such as gas stick assemblies and integrated gas systems, etc.

![]()

Featured Product Introduction

Atomic Layer Deposition Diaphragm Valves

- Ultrahigh cycle life with high-speed actuation

- Quick response capable of valve opening or closing time of less than 5 ms

- Thermal actuator extends the life in applications where the body is heated

- Valves with inductive sensors, solenoid valve assemblies, heater cartridge and thermocouple holes are available

Pneumatic Diaphragm Valves with Locking Device

- Manual and pneumatic operating mechanisms prevent misoperation better than traditional pneumatic diaphragm valves

- Cv 0.3 with compact design

- Surface mount meeting SEMI PR 3.1 seal specification

- W-seal and C-seal available

Two-Step Pneumatic Diaphragm Valves

- Pneumatic actuated

- With high and low flow gas connections, high and low flow can be accurately switched to moderate the pressure rise in the cavity

- With cobalt alloy diaphragm

- High flow Cv 0.27, low flow Cv 0.02 ~ 0.12

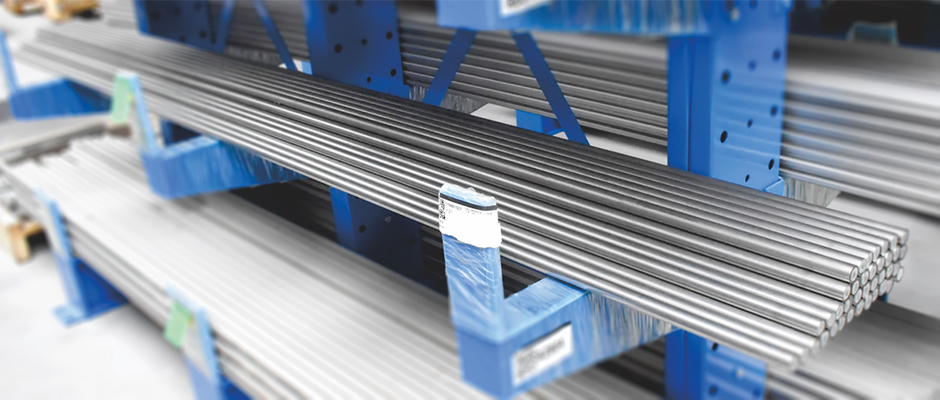

Stainless Steel Electropolished Tubing (EP Tubing)

- Materials: 316L, 316L VAR

- Inspection: visual inspection, surface roughness measurement, particle testing, moisture testing and a series of tests with scanning electron microscopy (SEM), Auger electron spectroscopy (AES), electron spectroscopy for chemical analysis (ESCA or XPS)

- Sufficient Inventory: FITOK can provide customers with one-stop solutions and professional services to help customers save procurement and inventory costs with flexible manufacturing systems and sufficient finished goods inventory in global warehouses

- Prefabrication services: fabricated EP bent tubing and EP tubing assemblies are available upon request to improve the installation efficiency for customers

- AGH series are applicable to high purity and ultra high purity fluid systems; AGL series are applicable to general gas fluid systems and oxygen-enriched environments

- AGH series are integrated from a diaphragm valve, a regulator and a pressure gauge; AGL series are integrated from a ball valve, a regulator and a pressure gauge

- Alloy diaphragm improves strength and corrosion resistance for long cycle life

- Modular design - shorten design time

- Surface mounting - easy installation and maintenance

- Miniaturization

- 316LV materials, electropolishing process and orbital welding

- W-seal / C-seal

Please see the Brochure of Products for Semiconductor Applications for more information. Should you have any questions, please contact us directly and We will reach you soon.

Related Articles:

.jpg)

.jpg)

Back

Back