FITOK Electropolished Tubing (EP Tubing) with Outstanding Surface Quality and Fast Delivery

Introduction

Electropolishing is a process in which metal undergoes a special anodic treatment in an electrolytic solution to obtain a smooth and bright surface. Stainless steel electropolished tubing (EP tubing) is a product processed from bright annealed tubing (BA tubing) by electropolishing the internal surface. FITOK has been adopting strict specifications for raw materials, electropolishing process, ultra-pure water cleaning, and packaging in cleanroom to effectively avoid contaminant residues and achieve better roughness, cleanliness, corrosion resistance and weldability of stainless steel EP tubing. FITOK stainless steel EP tubing is widely used in high purity and ultra high purity fluid systems in semiconductor, pharmaceutical, fine chemical, food & beverage, analytical and other industries.

Specifications

FITOK EP tubing, including TEP series and PEP series, is available in standard lengths of 20 ft, 4 m and 6 m, etc. to meet customers’ varying requirements. The internal surface can be electropolished to roughness of Ra ≤ 5 μin (0.13 μm), and the external surface to roughness of Ra ≤ 40 μin (1 μm).

Table 1

| Product | Standard | O.D. | External Surface Roughness | Internal Surface Roughness | Length |

| TEP Series | ASTM A269/A632 | 1/4”-2 1/2” | Ra ≤ 40 μin (1 μm) | Ra ≤ 5 μin (0.13 μm)Ra ≤ 7 μin (0.18 μm)Ra ≤ 10 μin (0.25 μm) | 20 ft, 4 m and 6 m |

| PEP Series | JIS G3459 | 6A-50A | 4 m and 6 m | ||

| ASTM A312 | NPS 1/8-NPS 2 | 20 ft, 4 m and 6 m | |||

Advantages

FITOK EP tubing is made of customized 316L SS, 316L SS VAR complying with SEMI F20 standard. 316L is commonly used for high purity (HP) and ultra high purity (UHP) products, which has excellent corrosion resistance and oxidation resistance. 316L VAR reduces non-metallic inclusions by special refining to enhance the purity of the materials. Customers can choose different materials according to their actual needs. The specific composition is detailed as follows:

Table 2

| Grade | Standard | FITOK Designator | Composition % | |||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | |||

| 316L | ASTM | 6L | ≤ 0.035① | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | ≤ 1.00 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| JIS G3459 | ≤ 0.03 | 12.0-16.0 | ||||||||

| 316L VAR | ASTM | 6LV | ≤ 1.50 | ≤ 0.01 | 10.0-15.0 | |||||

① The carbon content of tubing with outside diameter smaller than 1/2" or wall thickness smaller than 0.049" is allowed up to 0.04%.

The internal surface of FITOK EP tubing is electropolished to improve the smoothness of the flow path and form a chromium-rich layer on the metal surface to improve corrosion resistance. Electropolished tubing is subject to passivation treatment to remove free iron ions.

Relevant standards for electropolishing and passivation treatment:

- ASTM E1558 Standard Guide for Electrolytic Polishing of Metallographic Specimens

- ASTM A380 Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems

- ASTM A967 Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts

The internal surface of FITOK EP tubing can meet the following test standards after electropolishing:

Table 3

| Test Item | Test Standard |

| Surface roughness Ra | SEMI F37 |

| Oxide layer thickness | SEMI F72 |

| Surface defects | SEMI F73 |

| Cr/Fe | SEMI F60 |

| CrO/FeO | |

Test methods include visual inspection, dimension inspection, surface roughness measurement, particle inspection, moisture testing, SEM, AES and ESCA or XPS.

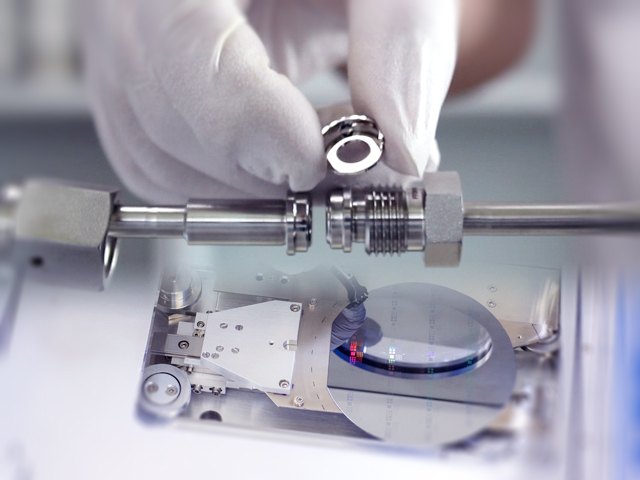

FITOK EP tubing can effectively avoid contaminant residues with strict cleaning and packaging processes. EP tubing is ultrasonically cleaned, washed and rinsed, then purged and dried with ultra high purity hot nitrogen before being packaged in the NEBB-certified ISO 4 cleanroom.

FITOK EP tubing packaging complies with SEMI E49 standard. It is cleaned with ultra high pressure nitrogen, end capped, and bagged in double polyethylene bags with the inner bag filled with ultra high purity nitrogen to ensure the product’s cleanliness and maximize the protection of the product in the logistics and transportation process from damage.

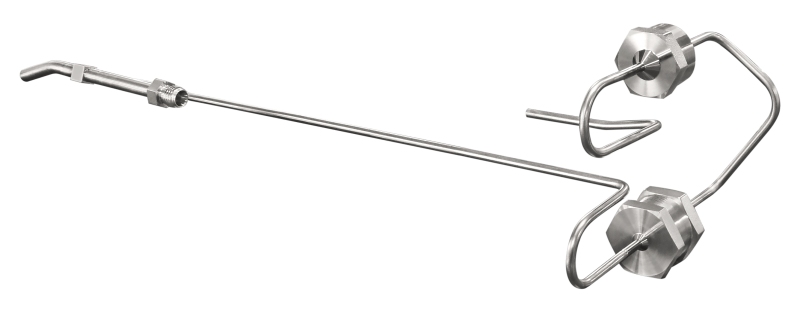

FITOK can provide EP bent tubing upon customer's request. EP bent tubing integrate with FITOK high purity products (such as all-welded check valves, face seal fittings, welded fittings, diaphragm valves, regulators, etc.) to form EP bent tubing assemblies. FITOK can prefabricate EP bent tubing assemblies according to customers’ requirements to help customers improve installation efficiency.

Figure 1 Prefabricated EP Bent Tubing Assemblies

As the global semiconductor industry develops, the demand for high purity components like EP tubing meeting the high cleanliness and high performance requirements of the semiconductor manufacturing industry is growing. As a global leading supplier of valves, fittings and tubing, FITOK can provide customers with one-stop solutions and professional services. With flexible manufacturing systems, mature and complete supply chain systems and warehousing systems, as well as sufficient finished goods inventory, FITOK can help customers save procurement and inventory costs and achieve fast delivery.

FITOK plant for stainless steel straight tubing, coiled tubing and etc. has obtained ISO 9001 quality management system certification with an annual production capacity of 500,000 m EP tubing. FITOK has enough inventory of EP tubing to meet your demand, please contact us for more information.

Please see the EP Tubing Catalog for more information. Should you have any questions, please contact us directly and We will reach you soon.

Related Articles:

.jpg)

.jpg)

Back

Back