FITOK 20D Series Medium Pressure Tube Fitting Explained (I) Construction and Performance

FITOK 20D series medium pressure tube fittings are widely used in oil and gas, chemical, power and hydrogen industries for their good performance such as the reliable sealing performance, high working pressure (up to 20,000 psig), high resistance to vibration and corrosion, easy installation and etc.

Construction Introduction and Working Principle

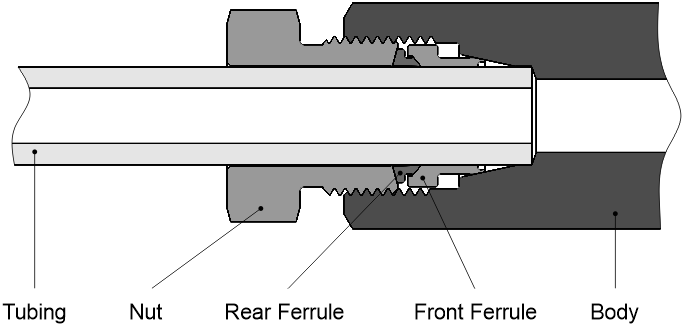

20D series tube fittings consist of four parts: fitting body, front ferrule, rear ferrule and nut (Figure 1). Standard high strength 316 stainless steel fittings can be connected to T20D series cold-drawn 1/8-hard seamless tubing, T15A series heavy-wall annealed seamless tubing and T20M series tubing.

Figure 1 Construction Diagram of Tube Fittings

The working principle of FITOK tube fittings is as follows:

- When the ferrule nut is tightened, the rear ferrule is driven to advance the axial motion of the front ferrule in the fitting body, while the fitting body squeezes the front ferrule inward to eliminate the gap between the front ferrule and the tubing. As a result, the front ferrule grips the tubing tightly.

- Further tighten the ferrule nut, the rear ferrule compresses the outer cone surface of the front ferrule to create expansion deformation, forming a seal between the front ferrule and the inner cone surface of the fitting body, and the front ferrule is compressed inward to further deform the tubing, forming a seal between the front ferrule and the tubing. At the same time, the rear ferrule grips the tubing under the compression of the front ferrule and ferrule nut.

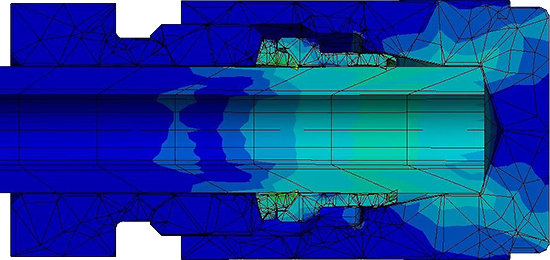

- Continue to tighten the nut, the rear ferrule squeezes the tubing further inward to create elastic deformation to support the front ferrule, preventing the front ferrule from loosening and creating further expansion deformation to the front ferrule, as shown in Figure 2.

Figure 2 Working Stress Distribution Diagram of Tube Fittings

Performance Features

FITOK 20D series tube fittings have been proven in FITOK labs and engineering applications to provide the following excellent performance:

- Reliable sealing performance

- High pressure resistance

- Excellent temperature compensation performance

- Stable corrosion resistance

- Highly resistant to vibration

- Reliable performance after repeated disassembling

Reliable sealing performance

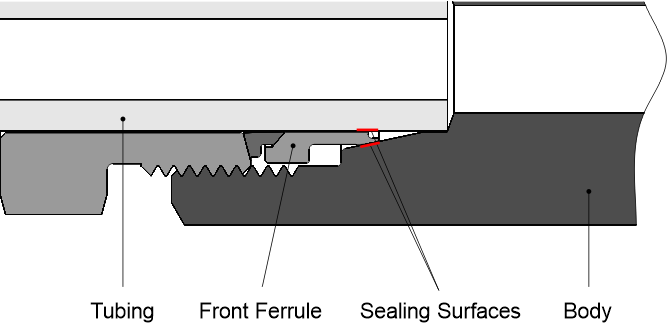

The sealing surfaces of FITOK 20D series tube fittings are shown in the figure.

Figure 3 Sealing Diagram of FITOK 20D Series Tube Fittings

FITOK has been adopting strict design and continuous optimization for 20D series tube fitting construction, strictly controlling the surface roughness and tolerance of the inner cone surface of the fitting body and the outer cone surface of the front ferrule, and employing advanced surface treatment technology to ensure a tight fit and eliminate the gap between the sealing surfaces. When the fitting is installed, the front ferrule fits closely with the fitting body and the tubing under the compression of the rear ferrule to ensure a reliable seal under fluid pressure.

The following table shows the results of the helium leak test for FITOK 20D series tube fittings. The test is performed following SEMI F1-96 standard at an ambient temperature of 64°F(18°C), where:

Inboard test: leak test with helium spraying for 15s under vacuum conditions inside the fitting.

Outboard test: leak test within 1 min when a mixture of helium at 1 atm pressure and nitrogen at 20,000 psig working pressure is introduced inside the fitting.

Table 1 Helium Leak Test Results for 20D Series Tube Fittings (Ambient Temperature)

| O.D.×W.T. (in) |

Inboard | Outboard | ||

| Vacuum Degree (mbar) |

Helium Leak Rate (mbar•L/s) |

Vacuum Degree (mbar) |

Helium Leak Rate (mbar•L/s) |

|

| 1/4×0.065 | 1.2×10-3 | 6.4×10-10 | 8.0×10-3 | 3.3×10-9 |

| 3/8×0.083 | 1.1×10-3 | 6.7×10-10 | 5.5×10-3 | 4.6×10-9 |

| 1/2×0.109 | 1.2×10-3 | 1.3×10-10 | 2.8×10-3 | 2.4×10-9 |

| 9/16×0.125 | 1.2×10-3 | 8.5×10-10 | 2.5×10-3 | 2.1×10-9 |

| 3/4×0.165 | 1.2×10-3 | 1.1×10-10 | 6.6×10-3 | 2.5×10-9 |

The results of FITOK lab tests and engineering applications show that FITOK 20D series tube fittings have excellent sealing performance.

High pressure resistance

The maximum working pressure of FITOK 20D series tube fittings is 20,000 psig. When connecting with FITOK T20D series tubing, the burst pressure of 20D series tube fittings can reach 3 times the maximum working pressure, up to 60,000 psig without system loosening or leakage.

Excellent temperature compensation performance

The front ferrule of a well-installed FITOK 20D series tube fitting exhibits a certain bulge deformation and this elastoplastic deformation may compensate for thermal deformation to some extent. When the temperature changes, elastoplastic deformation of the front ferrule can compensate for the dimensional changes caused by the temperature to achieve continuous reliable seal.

Table 2 and Table 3 show that FITOK 20D series tube fittings continue to perform well in extreme high and low temperature conditions.

Table 2 Performance of FITOK 20D Series Tube Fittings for a Low Temperature Application (Excerpt) (Helium Sniffer Leak Testing)

| O.D.×W.T. (in) |

Temperature (°F) |

Internal Pressure (psi) |

Vacuum Degree (mbar) |

Helium Leak Rate (mbar•L/s) |

| 1/4×0.065 | -323 | 6090 | 3.9×10-2 | 2.7×10-7 |

| 3/8×0.083 | -323 | 6090 | 8.3×10-2 | 2.8×10-7 |

| 1/2×0.109 | -323 | 6090 | 1.8×10-2 | 2.1×10-7 |

| 9/16×0.125 | -323 | 6090 | 3.4×10-2 | 1.4×10-7 |

| 3/4×0.165 | -323 | 6090 | 4.8×10-2 | 2.1×10-7 |

Table 3 Performance of FITOK 20D Series Tube Fittings for a High Temperature Application (Excerpt)

| O.D.×W.T. (in) |

Pressure Maintaining at High Temperature | Leak Test at Ambient Temperature | |||||

| Pressure/psi | Temperature/°F | Time/h | Result | Pressure/psi | Time/h | Result | |

| 1/4×0.065 | 11850 | 801 | 2 | No pressure drop | 15000 | 1 | No pressure drop |

| 3/8×0.083 | 11850 | 801 | 2 | No pressure drop | 15000 | 1 | No pressure drop |

| 1/2×0.109 | 11850 | 801 | 2 | No pressure drop | 15000 | 1 | No pressure drop |

| 9/16×0.125 | 11850 | 801 | 2 | No pressure drop | 15000 | 1 | No pressure drop |

| 3/4×0.165 | 11850 | 801 | 2 | No pressure drop | 15000 | 1 | No pressure drop |

Note: The pressure-temperature rating at 801°F is 0.79.

Stable corrosion resistance

Losses caused by material corrosion can reduce the wall thickness of components and lead to mechanical failure more easily.

FITOK 20D series tube fittings are made of special customized high strength 316 stainless steel, whose corrosion resistance has been improved greatly.

Table 4 Material Composition (%) of FITOK 316 Stainless Steel

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.04-0.065 | 2.00 | 0.045 | 0.030 | 1.00 | 17.0-18.0 | 12.0-14.0 | 2.0-3.0 |

The American Society for Testing and Materials (ASTM) requires a minimum of 10% nickel and 16% chromium in 316 stainless steel. The higher nickel and chromium content of FITOK 20D series tube fittings exceeds industry standard requirements, ensuring superior corrosion and hydrogen embrittlement resistance. For the application of rigorous working conditions such as high-pressure hydrogen and marine corrosion environment, FITOK can provide FITOK tailor-made 316/316L stainless steel, its molybdenum content no less than 2.6%, nickel content greater than 12%, nickel equivalent ≥ 28.5%, which has better corrosion resistance and hydrogen embrittlement resistance.

The salt spray test performed according to ISO 9227-2006 standard shows that 20D series tube fittings have no corrosion in 144 hours at 5% salt spray condition. Currently, FITOK 20D series tube fittings have been certified to EC79/2009/406/2010.

Highly resistant to vibration

During the installation of FITOK 20D series tube fittings, the front ferrule grips the tubing for its unique geometric design causing plastic and elastic deformation of the sealing cone surface and the body, and the elastic deformation allows the sealing cone surface to withstand certain vibrations. In addition, when the rear ferrule squeezes the front ferrule, it can grip the tubing at the right time, providing sufficient gripping force and effective support for the front ferrule to prevent the front ferrule from loosening.

The effective support and reliable grip of the front and rear ferrules provide 20D series tube fittings with excellent anti-vibration performance.

Reliable performance after repeated disassembling

Repeated use of fitting assemblies can cut your cost down significantly. FITOK 20D series tube fittings are designed to be reassembled many times with excellent construction design, precise tolerance control and superior surface finish. Tests have shown that the fittings maintain good sealing performance and proof pressure performance after 25 times repeated disassembling.

WARNING:

1. The relevant test results listed in this article are obtained under laboratory conditions and should not be considered valid outside of these conditions; laboratory tests cannot replicate various actual operating conditions and the test results are not statistically significant.

2. Due to the timeliness of the article, the test data listed in this article is for reference only, please contact FITOK Group for the latest data.

Related Articles:

.jpg)

.jpg)

Back

Back