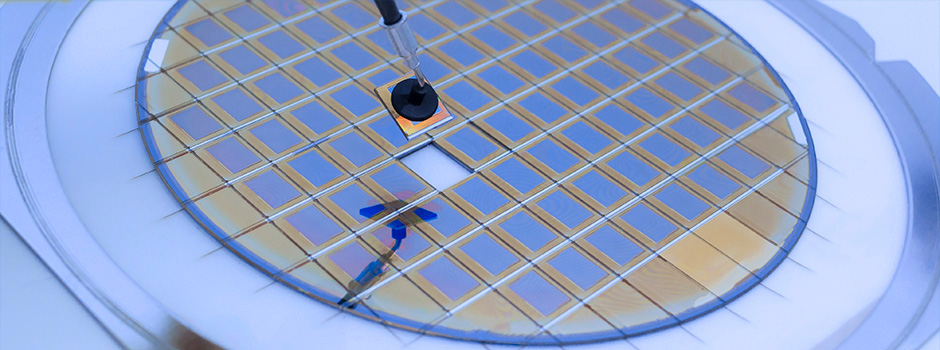

Metal Gasket Face Seal Fittings for the Semiconductor Industry

Why do metal gasket face seal fittings meet the needs of the semiconductor industry?

The semiconductor industry continues to pursue smaller and lower-power consumption chips, so the process nodes are getting smaller, which places higher demands on process cleanliness. Substandard cleanliness may lead to product quality defects, or even spread contamination of the entire product line, resulting in serious consequences of product scrap.

In high purity and ultra high purity (UHP) fluid systems used in the semiconductor industry, the selection of fittings is one of the key points. Weld fittings are often selected but they are not suitable for connections that require regular replacement or maintenance, while the non-metallic materials of O-ring face seal fittings may be incompatible with the media. Are there fittings that is easy to install and disassemble, compatible with the media, and can ensure a reliable seal? The answer is metal gasket face seal fittings. The main advantages of these fittings, which use metal gaskets as sealing elements, are as follows:

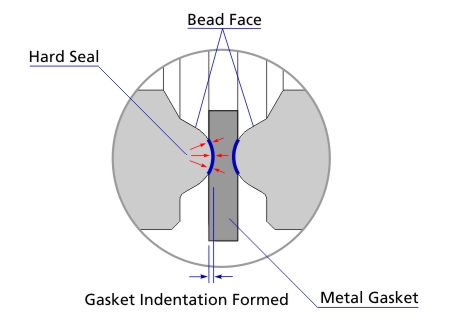

- Metal-to-metal hard seal, good sealing performance: When tightening the nut, the gland at both ends will squeeze the metal gasket from both directions, and since the hardness of the gland sealing surface is higher than that of the metal gasket (FITOK 316L stainless steel gland sealing surface is 109 HV harder than gaskets of the same material, and 158 HV harder than nickel gaskets), the metal gasket will be slightly deformed, and a tight face seal will be formed between the gland and the metal gasket to ensure the sealing performance. For FITOK products, the maximum helium leak rate is 4x10-9 std cm3/s when using silver-plated 316L stainless steel, silver-plated nickel and copper gaskets, and the maximum helium leak rate is 4x10-11 std cm3/s when using 316L stainless steel and nickel electropolished gaskets;

- Repeated reassembling and use: Squeezed metal gaskets do not damage the sealing surface of the gland, so they can be reassembled and used repeatedly with only one gasket change per time, resulting in low maintenance costs;

- No dead zone, no residue and easy to purge: The structure of the metal gasket face seal fittings allows the sealing element to be completely purged by the gas, thus eliminating the risk of contamination due to residue;

- Easy to install and disassemble: These fittings are easy to be installed and disassembled with conventional tools only, which can significantly improve the efficiency of installation and maintenance.

What are the products of FITOK FR Series Metal Gasket Face Seal Fittings?

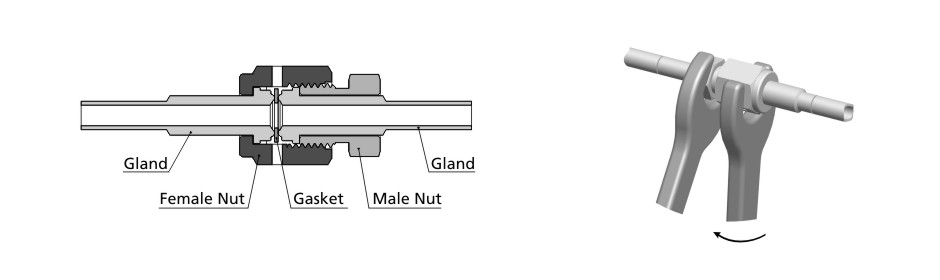

A typical metal gasket face seal fitting assemblies consist of the glands, gasket, female nut and male nut. In addition to these parts, FITOK FR series metal gasket face seal fittings also include body, plug, cap, flow restrictor locking device, etc.

Among them, the metal gasket needs to be replaced after each disassembling, and currently FITOK offers 7 kinds of metal gaskets:

1.Non-retained gasket: the most commonly used gaskets;

2.Gasket retainer assembly: the gasket is fixed to the sealing surface of the glands by the retainer, so they are not limited by the installation direction and the gasket is perfectly centered;

3.Side-load retainer: radial mounting, suitable for installation in tight spaces;

4.Blind gasket: as a temporary plug;

5.Snubber gasket: metal filter in the hole to reduce the influence of pressure fluctuations in the pipeline;

6.Knurled gasket: the outer ring of the gasket is knurled and engages the gland after installation to prevent loosening;

7.Restriction gasket: designed for precise flow control;

8.Ruby orifice restriction gasket: ruby orifice for high-temperature tolerance, broad chemical compatibility, and wear resistance.

Proper operation according to FITOK installation instructions is necessary to ensure sealing performance. First check the sealing surface of the fitting and the gasket for serious scratches and other defects, make sure the sealing surface is in good condition, then assemble the gland, gasket, female nut and male nut, and finger tighten the nut. Use a wrench to further tighten the female nut while keeping the male nut stationary, 1/8 turn for stainless steel and nickel gaskets (Note: 3/8 turn for knurled gaskets) and 1/4 turn for copper gaskets. For details, please see Installation Instructions for Metal Gasket Face Seal Fittings.

FR series metal gasket face seal fittings Installation Instructions

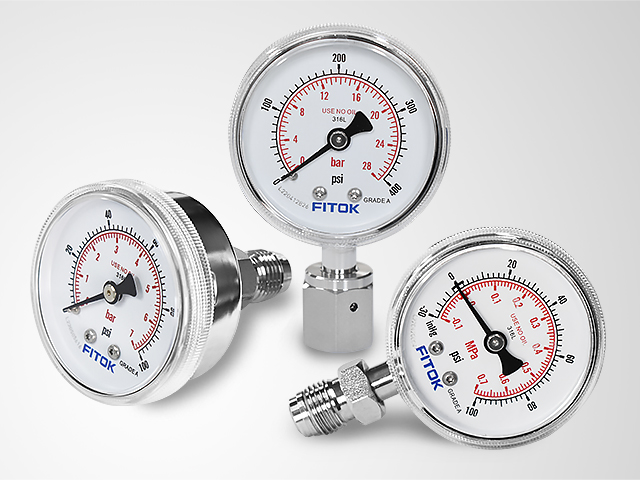

FITOK offers a comprehensive range of high purity and ultra high purity products, including diaphragm valves, bellows-sealed valves, metering valves, pressure regulators, as well as gas control systems such as point-of-use panels, changeover systems and integrated gas systems, in addition to metal gasket face seal fittings and weld fittings. Installation instructions and training services are also available. FITOK is always committed to meeting the different needs of our customers with specialized products and professional services, and continue to create values for our customers.

Related Articles:

.jpg)

.jpg)

Back

Back