New Product Launch: FITOK Canister Assemblies

Introduction

In atomic layer deposition (ALD) process, selecting the right precursor is critical for process control and film performance, etc. Meanwhile, based on the precursor properties such as volatility and reactivity, matching the right canister will have a synergistic effect on the process.

Through high quality control of the material selection to the molding process, CSR Series Canister Assemblies can accommodate the packaging and storage of most precursors and provide excellent safety and cleanliness for the entire deposition process.

Features

- Ultra high purity processes for ultra high purity applications

- Wetted metal parts are 316L stainless steel for broad chemical compatibility

- External surface mechanical mirror polished and internal surface electropolished to roughness Ra ≤ 10 μin. (0.25 μm)

- Leak rate (helium): ≤ 1.0x10-9 std cm3/s

- Connection size: 1/4" to 1/2"

- Connection type: metal gasket face seal fittings

- Customized volumes available upon request

Major Materials of Construction

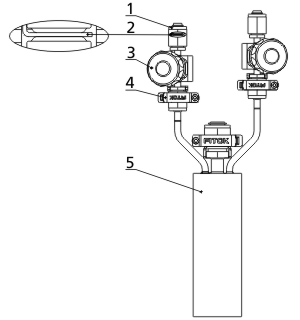

| Item | Component | Part Number Example | Material |

| 1 | Cap | 6L-CP-FR4 | 316L SS |

| 2 | Gasket | 6L-GT-FR4-AS-UP | 316L SS |

| 3 | Diaphragm Valve | DQ6L-RFR4-RF3 | 316L SS |

| 4 | Locking Device | S4-FR4-LD | 304 SS |

| 5 | Canister | CSR6L-50-ALD | 316L SS |

Note: Figure above shows the typical product type. For other types, please contact FITOK Group or our authorized distributors.

FITOK high quality diaphragm valves and metal gasket face seal fittings contribute to accurate and reliable flow rate and clean high purity gas delivery from canister assemblies.

Please see the product catalog for more information. Should you have any questions, please contact us directly and our sales and technical support will reach you soon.

Related Articles:

Back

Back