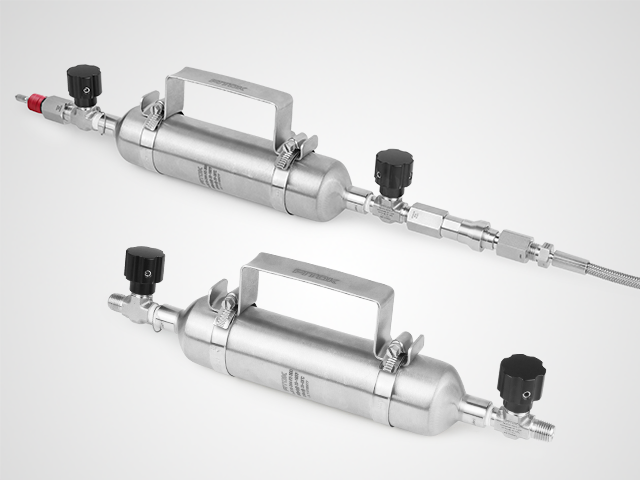

New Product Launch: FITOK Anti-Siphon Back Pressure Check Valves

Introduction

Chemical pumps are commonly used in the industries like oil and gas, chemical, pulp & paper, etc. The function is to inject a certain amount of chemicals into the system to improve production or prevent corrosion. Usually, anti-siphon valve, back pressure valve and check valve are installed downstream to ensure the chemical pump works properly.

FITOK CSV series anti-siphon back pressure check valves integrate three different functions into one, help you to save space, improve installation efficiency and reduce maintenance:

Anti-Siphon function: reduce unwanted siphoning due to wellhead or pipeline condition change.

Back pressure function: provide back pressure to keep the consistent output flow from chemical pump.

Non-Return function: prevent fluids flowing back to the chemical pump.

Features

- Integrate three different functions into one, fewer number of connections improve the system reliability

- Small size, light weight and low installation space requirements, easy for installation and operation

- Inline adjustment of cracking pressure with broad pressure range

- Patent pending

Technical Data

| Maximum Working Pressure | 10000 psig (690 bar) | |

| Working Temperature | 0 °F ~ 392 °F (-18 °C ~ 200 °C) | |

| Cracking Pressure Range | 50 ~ 450 psig (3.44 ~ 31.0 bar) | |

| Orifice Size | 0.189 in. (4.8 mm) | |

| Materials | Body, stem, bonnet | 316 SS |

| Sealing part | FKM, PTFE | |

| Flow | 3 GPM @ 1000 psig | |

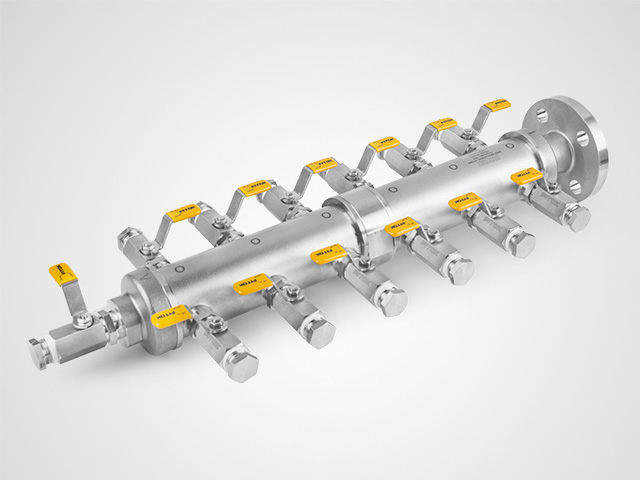

In addition to the CSV series anti-siphon back pressure check valves, FITOK also provides a variety of general instrumentation check valves (CV, CH, CO, CA, COA, CL and CW series) and medium and high pressure check valves (10C, 10CO, 15C, 15CO, 20C, 20CO, 60C and 60CO series) for different applications.

Please see the product catalog for more information. Should you have any questions, please contact us directly and our sales and technical support will reach you soon.

Related Articles:

Back

Back