New Product Launch: FITOK Ruby Orifice Restriction Gaskets

07/25/2024

1230

Introduction

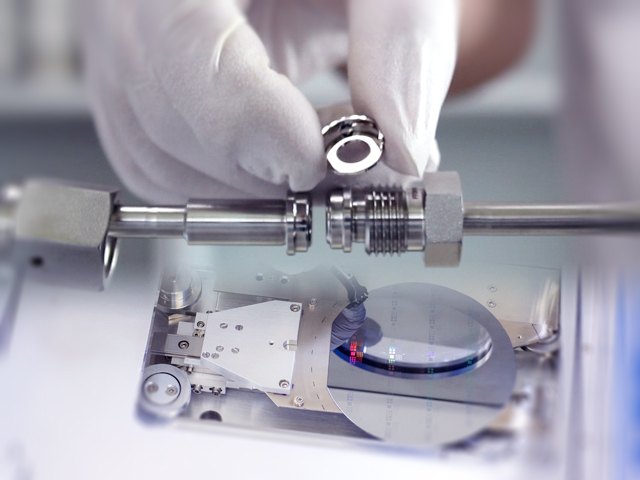

FITOK Ruby Orifice Restriction Gaskets are precision-engineered flow control elements made with high-precision ruby, ensuring accurate fluid flow control in pipelines. With exceptional resistance to abrasion, corrosion, and high temperatures, these gaskets provide reliable performance under harsh conditions. They are widely used in semiconductor etching equipment.

Features

- Laser-drilled orifices are uniformly ground using diamond wire, ensuring high precision and excellent flow consistency.

- Advanced crimping process secures the ruby to the gasket, ensuring minimal particle generation and high cleanliness.

- Superior chemical corrosion resistance, suitable for corrosive etching environments involving aggressive chemicals or gases.

- High hardness and abrasion resistance maintain the orifice shape during etching, minimizing particle generation.

- Excellent thermal stability allows endurance to high temperatures in etching equipment without deformation or damage.

- Good transparency to specific wavelengths of light in certain etching processes involving optical monitoring or control.

Technical Data

| Gasket Type | FR Face Sealed | C-Seal Surface Mounted |

| Size | 1/8”, 1/4”, 1/2” | 1.125” |

| Max. Working Pressure | 145 psig (10 bar) | |

| Working Temperature | -320.8 ~ 725 °F (-196 ~ 400 °C) | |

| Orifice Size | 0.0015” ~ 0.0350” | |

| Flow Deviation | Within ±5% | |

| Helium Leak Rate | ≤ 4×10-11 std cm3/s | ≤ 1×10-9 std cm3/s |

In addition to Ruby Orifice Restriction Gaskets, FITOK offers ordinary restriction gaskets and metal face seal gaskets to meet various application needs.

Please see the Metal Gasket Face Seal Fittings Catalog and Integrated Gas System Catalog for more information. Should you have any questions, please contact us directly and we will reach you soon.

Related Articles:

Back

Back