Introduction to W-Seal and C-Seal

Integrated Gas Systems (IGS) used in semiconductor equipment typically consist of components such as diaphragm valves, check valves, regulators, filters, pressure sensors, mass flow controllers, and substrates. These components are usually surface-mounted and are sealed using either W-seal or C-seal. The choice of sealing type is crucial in determining the system’s sealing performance. In this Tech Talk, we will discuss the similarities and differences between W-seal and C-seal.

Similarities between W-Seal and C-Seal

W-seal and C-seal are both types of metal seals. Unlike non-metal seals like rubber or composite, metal seals do not deteriorate over time due to compacting, and they have good chemical compatibility. FITOK W-seal gaskets (IWG series) and C-seal gaskets (ICG series) are made of 316L or 316L VAR stainless steel in accordance with FITOK Ultra High Purity Process (FC-03). These gaskets are electro-polished to reach a surface roughness of Ra ≤ 5 μin. (0.13 μm), which conforms to SEMI F19 UHP. With excellent sealing performance, their sealing face leak rate (helium) ≤ 1×10-9 std cm3/s.

Compared to weld seal or metal gasket face seal, W-seal and C-seal are more compact and can significantly reduce the size of gas delivery systems. For occasions requiring limited flow, sealing gaskets with specified orifice are available.

Differences between W-Seal and C-Seal

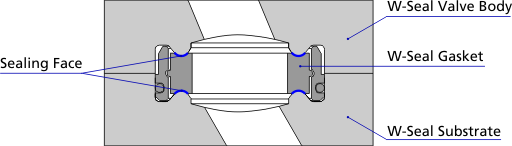

W-seal gaskets (IWG series) are designed with a "floating" structure, enabling the sealing face to be independent of components receiving external forces. During installation, the sealing face of the gasket compresses against the surface-mounted components (like W-seal valve body) and substrates and forms the seal. Each W-seal can be installed in the system individually, making it easy to remove and reinstall as system layouts are modified. In addition, FITOK service kit (Model No.: SC-IGS-11) offers gasket tweezers for W-seal gaskets to ensure a quality installation of the gasket.

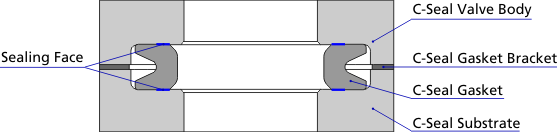

The section of a C-seal gasket (ICG series) resembles the letter "C" with two flat sealing bosses on both sides. When properly tightened, the top and bottom of the gasket smash against the surface-mounted components (like C-seal valve body) and the hardened sealing faces of substrates and create seals. In addition, the C-seal gasket bracket can help to locate multiple gaskets at one time.

For any Integrated Gas System (IGS), either W-seal or C-seal can fulfill requirements. However, due to different SEMI standards applied, sealing gaskets and sealing faces vary in construction. Customers can choose a W-seal or C-seal based on usage habits and component sealing types.

Related Articles:

.jpg)

.jpg)

Back

Back