FITOK Sampling Systems for FPSOs

An FPSO (Floating Production Storage and Offloading) vessel is a comprehensive offshore oil production facility that serves as a large-scale base for oil and gas operations. It integrates various functions including production, processing, storage, transportation, and command systems for both living and production purposes. This enables it to effectively carry out tasks such as oil production, storage, and unloading. The FPSO typically operates in conjunction with underwater oil extraction devices and shuttle tankers to form a complete production system. FPSO utilizes submarine oil pipelines to receive the mixture of oil, gas, and water from underwater oil wells. This mixture is then processed to produce high-quality crude oil and natural gas. Additionally, the FPSO can handle other important operations such as treating oily wastewater, power generation, and providing heating services. Currently, FPSOs are widely used in offshore environments due to their versatility and have become an essential component in modern offshore oil development projects.

Challenges Faced by Sampling Systems in FPSO Applications

The application of sampling systems on FPSO vessels is crucial as it ensures the accuracy and reliability of key parameters and indicators during oil and gas field development. The sampling system collects and analyzes products and process media at various stages within the FPSO, such as crude oil, hydrocarbon liquids, natural gas, fuel for storage tanks, process water, steam, seawater, and cooling media. It is a critical component of the topside module of the FPSO. Compared to sampling systems used in other fields, the sampling systems for FPSOs operate under more challenging environments.

Due to the harsh working environment of FPSOs, sampling systems used for FPSOs face more challenges. FITOK, with extensive experience in designing and manufacturing sampling systems, has accumulated a wealth of product and application knowledge to help you easily overcome these challenges.

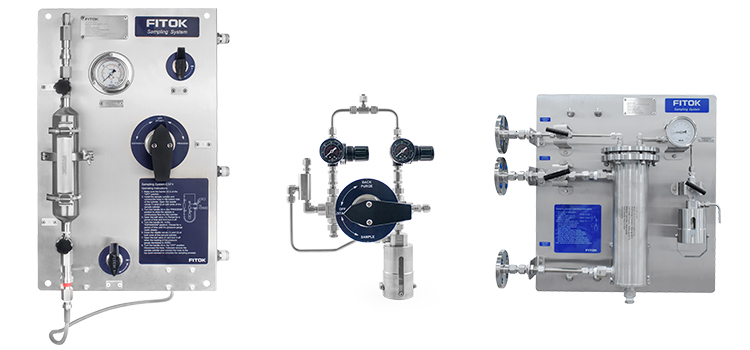

FITOK Sampling Systems

High Temperature and High Chlorine Environments

FPSO vessels are typically located in remote deep-sea areas, facing extreme climate conditions and marine environments, such as high temperatures and corrosive chloride environments. These conditions impose high requirements on the corrosion resistance performance of sampling systems.

In response to the corrosive environment of high temperature and high chloride-containing media, FITOK uses tailor-made 316 stainless steel material, with nickel and chromium content approaching the upper limit value (nickel content of 12-14%, chromium content of 17-18%) specified by ASTM A479/A182 standards. This provides better corrosion resistance, high-temperature resistance, and higher strength. Additionally, FITOK tailor-made 316/316L stainless steel meets the chemical composition requirements for 316L in relevant standards, while also satisfying the mechanical property requirements for 316 in those standards. Its molybdenum content exceeds 2.6%, effectively improving its resistance to pitting corrosion and providing superior corrosion resistance in marine atmospheric environments containing chlorides. In addition to 316 stainless steel, FITOK can provide higher-grade alloys, including super duplex stainless steel (2507), Hastelloy C-276, alloy C-400, etc., offering higher corrosion resistance in high-temperature and chloride-containing media environments.

Sour Service Conditions

In the production of oil and gas, hydrogen sulfide (H2S) is a common sour corrosive gas. In the sour environment of petroleum, seawater, and H2S mixtures, stress corrosion cracking (SCC) and sulfide stress cracking (SSC) pose a synergistic threat, leading to material embrittlement and severely affecting the reliability of sampling systems.

To address the impact of sour corrosion in oil and gas sampling, FITOK can provide products made from materials that comply with NACE MR0175 standards for use in sour service. This includes specially annealed 316 stainless steel (with nickel content of 12-14%, chromium content of 17-18%), alloy C-400, Hastelloy C-276, etc., to minimize the impact of hydrogen sulfide environments on sampling systems and ensure their reliability and stability.

Long Periods of Offshore Working

FPSOs are generally located far from shore and operate for long periods offshore. Compared to sampling systems on land, which can be easily maintained, sampling systems on FPSOs need to work continuously for longer periods. This imposes higher requirements on the reliability and maintainability of the system.

FITOK boasts excellent product quality assurance, with our sampling system complying with DNV-OS-E201 Class II equipment standards. Additionally, our welding procedure files (WPS/QPR/WQT) have received approval from Lloyd's Register. Main components such as sampling cylinders, needle valves, quick-connects, fittings, hoses, tubing, and coolers are all manufactured by FITOK and tested in our factory. FITOK sampling systems undergo rigorous quality testing throughout the design, and production assembly processes to ensure high-level reliability and maintainability required for long-term offshore work on FPSOs. The fittings used in FITOK sampling systems, such as 6D series tube fittings, have passed all standard tests and supplemental tests under ASTM F1387 standards to prevent leakage of hazardous substances during long-term offshore operations and ensure operator safety and environmental protection. Not only that, the FITOK sampling system adopts a user-friendly design, making operation and maintenance simpler and more convenient. To further enhance the user experience, FITOK also provides comprehensive professional training services to ensure that customers can quickly become proficient in using our products efficiently.

Limited Installation and Maintenance Space

FPSOs are complex offshore oil and gas production facilities that require meticulous planning and space management for the installation of various systems and equipment. Due to the need for optimizing layouts and integrating multiple systems, the available space on FPSOs is extremely limited, which poses challenges for the installation of sampling systems used for monitoring and analysis.

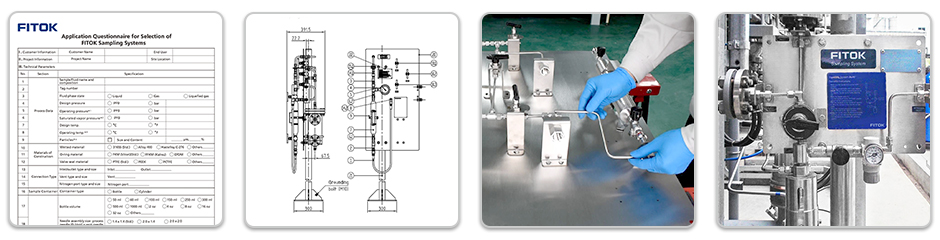

FITOK has extensive experience in designing and manufacturing sampling systems and can provide customized designs tailored to customer requirements and actual operating conditions. We can optimize product layouts, considering ergonomics while ensuring functionality and reliability. This enables the convenience of operating the sampling system within a limited space, maximizing customer satisfaction.

Tight Project Schedules

The sampling system needs to be integrated with other production facilities on the FPSO. This includes connecting them to pipelines or storage tanks for sample collection. Any delays in delivering and installing the sampling systems can disrupt the entire construction schedule and delay the start of production. After installation, rigorous testing and commissioning are necessary to ensure the proper functioning of the sampling systems. Delays in delivering the sampling systems can significantly affect the entire commissioning process. Therefore, it is crucial to deliver, install, and commission the sampling systems within specified construction schedules to ensure efficient operation.

FITOK has factories in the United States, Germany, and China, as well as warehousing and sales service centers in these countries along with the UAE. With over 600 tons of raw materials and more than 500,000 forgings in stock, FITOK can meet customers' special requirements promptly. Additionally, FITOK maintains sufficient finished product inventory in its global warehouses to help customers save on procurement and inventory costs. As a leading global supplier of valves and fittings, FITOK offers customers a one-stop solution with professional services including system design, assembly, training, on-site support, and spare parts supply.

FITOK One-Stop Solution Services

Other Products That Can Be Used on FPSOs

Apart from the sampling system, FITOK offers a wide range of excellent products suitable for FPSOs. These products are specifically designed for marine and petroleum environments, with features such as corrosion resistance, external pressure sealing structures, the impact of seawater pressure on valve moving parts, and the option of NACE MR0175 compliant materials. The related products are as follows:

FITOK not only offers a wide selection of sampling systems but also provides customized designs tailored to actual working conditions, addressing various challenges faced by FPSOs. Additionally, our technical expert teams, deployed in Europe, the US, the Middle East, and China, are ready to offer advice and assistance for any issues you encounter. We provide professional technical support, whether adhering to your existing designs or collaborating with you to develop a brand-new or improved solution.

Related Articles:

.jpg)

.jpg)

Back

Back