Common Methods to Obtain Representative Samples

Sampling analysis is a very critical part in petrochemical and other industries. Obtaining correct analysis results requires operators to carry out standardized operations step by step according to the standard operation process of the sampling system, and more fundamentally, and more importantly, the design of the sampling system requires to ensure that representative samples are obtained.

At present, the main off-line sampling method is to set up a branch sampling line on the process line to direct the medium into the sampling container, then bring the container to the analysis laboratory, and connect the analyzer for qualitative and quantitative analysis of medium components. As far as we know, many enterprises still use open sampling methods, as shown in Figure 1 below. The structure of open sampling is simple, just open the sampling valve to get the sample. But the drawbacks are also very obvious, such as the medium residues inevitably remain at the end of the sampling line, and the medium may react with the air or some components volatilize (which may be toxic and harmful), it is difficult to clean up after long-term sampling and pollutes the environment. Therefore, representative samples cannot be obtained, and the analysis results cannot represent the actual medium situation in the current line.

With higher requirements for environmental protection and the increasing attention paid by enterprises to the safety of personnel, it is the trend to adopt a safer and more environmentally friendly sampling method that can obtain representative samples. Several common improvement methods and suggestions are described below.

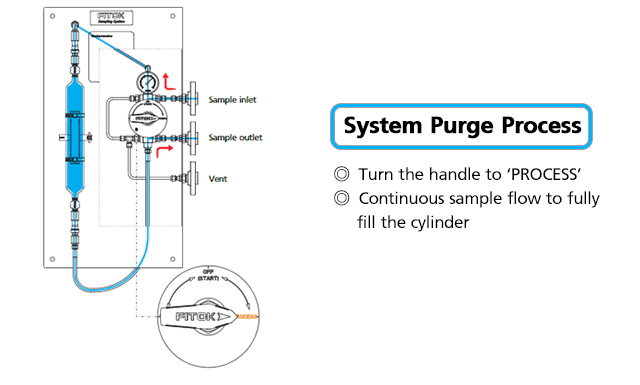

1.System purge before sampling (fast circulation loop)

System purge refers to purging the sampling line with the medium of the system so that fresh medium can flow to the sampling point. This structure requires a low-pressure end for medium circulation. The low-pressure end can be a low-pressure position in the system line, as well as a discharge port or flare port, and the medium purged by fresh medium and returned to the process line will not be considered as pollution to the main line. As shown in Figure 2, the sampling line is purged for a period of time before sampling, so that the old medium originally staying in the line is purged to the sample outlet, and fresh and representative samples can be obtained in the container after purging.

Please Watch Video of Operation Instruction for FITOK Sampling System with System Purge

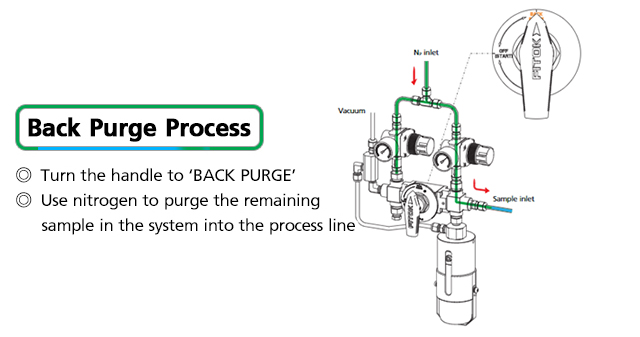

2.Back purge before sampling

When the system purge cannot be carried out, if there is no low-pressure end and discharge port on site, back purge can be used, i.e. inert gas (usually nitrogen) can be used to purge the medium staying in front of the sampling valve, so that this part of the medium can return to the main line. After a period of back purge, the fresh and representative medium flowing from the line is obtained during sampling. As show in Figure 3. Use conditions shall also be considered for back purge, such as the gas used in purge will not affect the production process when flowing into the main line, and the pressure provided by purging is higher than the inlet pressure of the sampling line, etc.

Please Watch Video of Operation Instruction for FITOK Sampling System with Back Purge

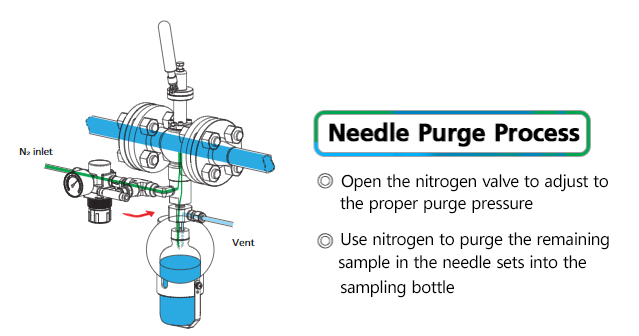

3.Needle purge before/after sampling

For glass bottle sampling methods (commonly used for low pressure liquid sampling), the sampling assembly includes a sampling valve, a sampling needle and a sampling bottle with gaskets. After each sampling, some sample medium will remain in the sampling needle more or less. This part of medium may deteriorate or volatilize toxic gas when directly contacting with air, and will be taken into the glass bottle first during the second sampling, thus affecting the representativeness of the sample. Therefore, it is also highly recommended to purge the sampling needle assembly after sampling, as shown in Figure 4. For higher requirements, in addition to needle purge, it is also recommended to use an empty sampling bottle in the sampling position during the out-of-service period of the sampling system.

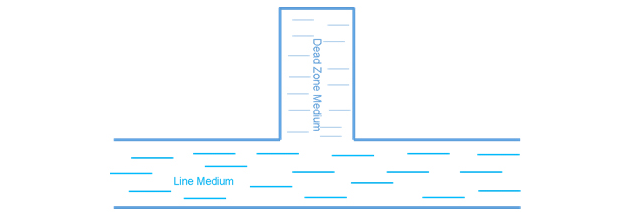

The medium in the dead zone cannot flow smoothly but the medium near the line will enter the line and contaminate the sample

Please Watch Video of Operation Instruction for FITOK Sampling System with Needle Purge

4.Avoid dead zones in the product structure or control dead zones in non-analysis branches.

The medium in the non-flowing position is usually the dead zone medium, which cannot represent the medium composition and state in the current line, so it is necessary to try to avoid taking the dead zone medium when sampling. Dead zones in conventional structures include: pressure gauge position, sensor position, bleed valve position and other places where Tee structure may occur.

The medium in the dead zone cannot flow smoothly but the medium near the line will enter the line and contaminate the sample

Therefore, if dead zone structure cannot be avoided in the sampling system, parts that will cause dead zone shall be installed on non-sampling lines, for example, pressure gauges can be installed on branch line; Use three-way valve instead of one Tee and two-way valve, etc. At the same time, using a higher flow rate can also reduce the influence of dead zone medium on the sample.

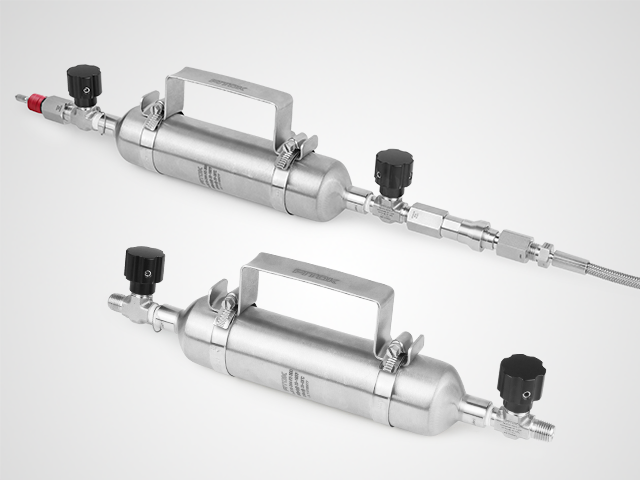

In addition to the common methods mentioned above, there are other methods that can help to obtain representative samples. For example, it is recommended to replace the gasket for each sample to avoid medium residue on the previous gasket and achieve better sealing effect. For some special applications, such as the analysis of trace sulfide, use SilcoNert® 2000 (Sulfinert®) coated cylinder to avoid the adsorption of trace elements, etc. Specific issues need to be analyzed in detail. For more sampling applications, please contact FITOK Group or our authorized distributors.

Please see the product catalog for more about sampling systems. Should you have any questions, please contact us directly and our sales and technical support will reach you soon.

Related Articles:

.jpg)

.jpg)

Back

Back