Why is the ND Series Needle Valve the Optimal Choice for Cylinder Sampling Control Valves?

In a sampling assembly, needle valves serve as critical control components installed at both ends of the cylinder. FITOK's cylinder sampling systems typically utilize the ND Series needle valves to regulate the inflow and outflow of media within the cylinder. So why are other valve series not chosen? The answer lies in the fact that the ND Series needle valves are better suited to the operational conditions of sampling cylinders. The advantages of the ND Series over other valves in cylinder sampling applications can be elaborated upon from the following perspectives.

Features of Different Valve Types

Needle valves, ball valves, diaphragm valves, and other types of valves are widely used in fluid systems, each offering unique features in different aspects. Compared to needle valves and ball valves, diaphragm valves are more expensive and better suited for ultra-high-purity applications, such as in the semiconductor industry, making them less common in sampling systems. Ball valves and needle valves are more frequently used in sampling systems. Due to their distinct characteristics, they are typically applied in different sections of the system.

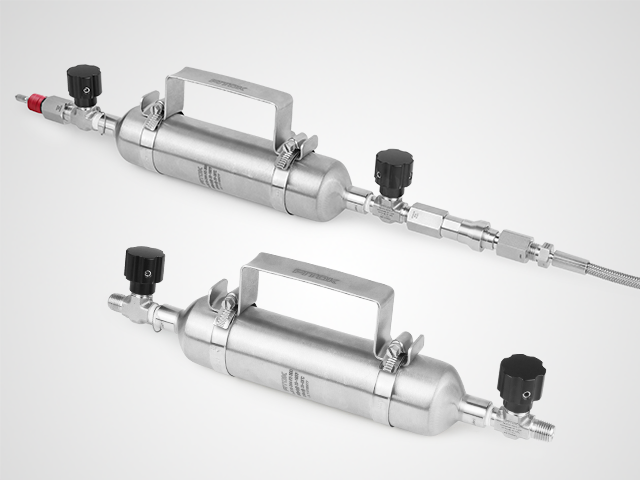

Figure 1 FITOK ND Series Needle Valve (left) and BV Series Ball Valve (right)

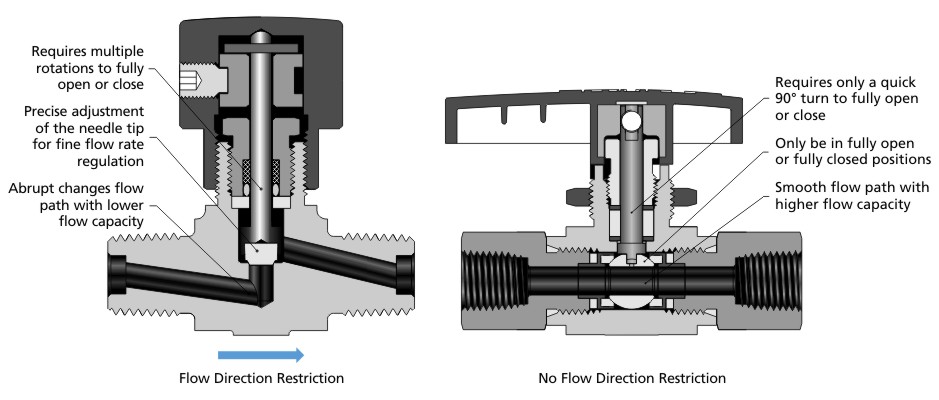

Table 1 The Features of Needle Valve and Ball Valve

| Item | Needle Valve | Ball Valve |

| Operation | Requires multiple rotations to open or close fully | Requires only a quick 90° turn to fully open or close the straight through ball valve |

| Flow Control | The threaded stem allows precise adjustment of the needle tip for fine flow rate regulation | Only be in fully open or fully closed positions, incapable of precise flow control |

| Flow Capacity | The flow path has abrupt changes, resulting in lower flow capacity and noticeable pressure drop when opening | Smooth flow path with large flow capacity, suitable for high-flow applications |

| Flow Direction | Generally has flow direction restrictions (marked by a flow arrow on the valve body) | Typically have no flow direction restriction |

| Application | Suitable for applications requiring flow regulation, infrequent operation, and low flow capacity requirements | Ideal for applications needing quick shut-off, frequent operation, and high flow capacity requirements |

Overall, needle valves are suited for applications where flow regulation is needed but infrequent operation and low flow capacity are acceptable. In contrast, ball valves are ideal for situations requiring quick shutoff, frequent operation, and higher flow capacity. For sampling cylinders specifically, the most critical task is safely transporting representative samples to the laboratory for testing without leakage after sampling is complete. In this case, there are no special requirements for rapid opening or high-flow capacity. But some degree of flow regulation is necessary to allow sampling media to enter or exit the cylinder at an appropriate rate. Therefore, compared to ball valves, needle valves are more suitable as control valves for sampling cylinders. Indeed, ball valves are more suitable for installation on sampling panels as sampling valves due to their operational convenience, high flow capacity, and visible open/close status indication characteristics, as exemplified by FITOK's BF Series and BO Series ball valves.

Features of the ND Series Needle Valve

FITOK offers a wide variety of needle valve series suitable for different applications. The ND series possesses several features that make it particularly well-suited as a control valve for sampling cylinders.

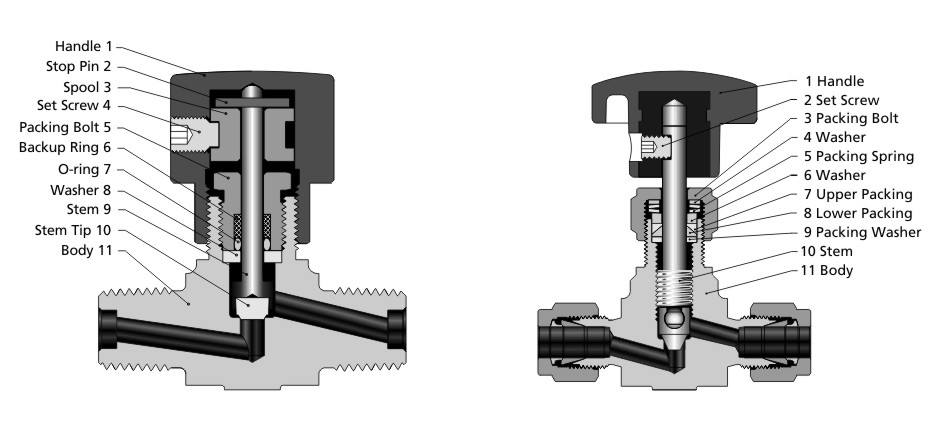

Figure 2 FITOK ND Series (left) and NG Series (right) Needle Valve Structures

Sampling cylinders need to be moved after collecting samples, which may involve potential impact risks. The FITOK ND series needle valve features a stem design that is protected by both the handle and valve body. Thus, when external forces act on the handle, the stem does not bear direct stress, preventing bending or failure. In contrast, most stems in other series are exposed and are more suitable for static working conditions. Additionally, the stem is fully enclosed by both the handle and valve body, helping to prevent contaminants from entering the valve's functional area and reducing the risk of external contamination affecting the valve's sealing performance.

Sampling cylinders must ensure the representativeness of contained samples. FITOK ND series needle valves employ a threadless stem design, eliminating potential contamination from threaded stem lubricants. In contrast, other needle valve series, such as the NG series, have threaded stems located below the packing and in direct contact with media. Lubricants and wear particles from these threads can easily contaminate the sample.

FITOK ND series needle valves feature a non-rotating stem structure with O-ring sealing, making them more wear-resistant and a more reliable external seal than other valve types with rotating stems and packing seals.

The lever-style handle on sampling cylinders presents a leakage risk during transport, as external impacts may inadvertently actuate the valve. In contrast, the round handle of the ND series needle valve is designed to effectively prevent accidental valve openings.

Sampling cylinders require portability to transport samples effectively. The structural dimensions (handle size, height) of the FITOK ND series needle valves are smaller, making them better suited for portable sampling cylinders.

Based on these characteristics, FITOK ND Series needle valves demonstrate significant advantages for sampling cylinders requiring portable transportation and representative sample collection, particularly in transport safety, compact dimensions, operational reliability and media contamination prevention.

Therefore, the FITOK ND series needle valve is the best choice for sampling cylinder applications. However, for high-pressure conditions, the NU series needle valve is more suitable than the ND series, as its union bonnet construction effectively avoids accidental valve disassembly. Additionally, both the ND series and NU series needle valves are available with TPED certification. Each FITOK TPED-certified needle valve undergoes internal and external leak testing with nitrogen or compressed air at 1.2 times the rated working pressure before shipment. For detailed information, please refer to the TPED needle valve catalog.

FITOK has extensive experience in designing and manufacturing sampling systems. We offer a wide range of models while also providing customized designs tailored to client specifications and actual working conditions, maximizing satisfaction with customer needs. Please leave a message if you have any questions, we’re happy to help. Send us an application questionnaire to get started with your sampling system.

Related Articles:

.jpg)

.jpg)

Back

Back