FITOK's Successful Delivery of Sampling Systems

Recently, FITOK successfully delivered a batch of Bottle Configuration Sampling Systems for Liquids to a leading chemical client for the construction of its new production line. As a globally recognized chemical enterprise, this client upholds exceptionally high standards for product quality. To meet these standards, specialized sampling equipment is essential for controlling the technical indices of process media and enhancing product purity and stability.

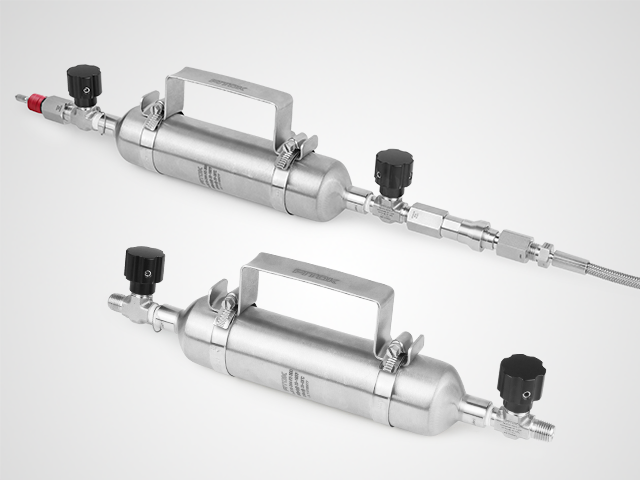

These systems are designed for installation directly on process pipelines using flanges, allowing for direct and efficient sampling. Equipped with a piston valve, the system ensures no residual sample through the retraction of the piston. This prevents subsequent sampling from contamination by the previous residual sample and ensures that each sample is representative. Additionally, the scale on the piston valve body provides a direct visual indication of the piston stroke, enabling users to determine the valve’s opening degree. The bottle configuration sampling system with a piston valve for liquids, with its specialized design, ensures non-clogging and leak-free sampling processes. It is particularly well-suited for handling highly viscous liquid media, such as crude oil and PBAT.

Bottle configuration sampling systems with a piston valves are available in four typical configurations: purge type (with needle purge function), fixed volume and purge type (with fixed volume sampling and needle purge functions), fixed volume type with heating/cooling jacket (with fixed volume sampling and needle purge functions while maintaining sampling within a certain range of temperature), and solvent purge type (with needle purge and solvent purge functions), for different working conditions.

In addition to offering various types of sampling systems for liquids, FITOK provides sampling systems for liquefied gases, sampling systems for gases, and sample handling systems, along with a variety of accessories (e.g. sample bottles, sample cylinders and needle assemblies). To meet diverse customer needs, FITOK provides customized designs tailored to specific working conditions. Each product undergoes strict quality control to ensure exceptional performance. Additionally, the FITOK Sampling System Software enhances user experience by offering product introduction, videos for sampling processes, and recommendations for sampling systems based on specific mediums and application settings, facilitating efficient product selection.

This successful delivery highlights FITOK’s product excellence and strengthens our valued partnership with the customer. Looking ahead, we remain committed to driving innovation, improving product performance, and delivering solutions that create value for our customers.

Related Articles:

Back

Back