Select the Right Hoses for Your Tire Curing Presses

Vehicles have become an indispensable part of people’s everyday lives. The performance of vehicles is highly dependent on reliable tires. Tough, durable tires not only help contribute to your vehicle's handling and performance, but can also impact fuel efficiency and safety.

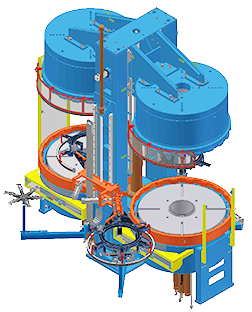

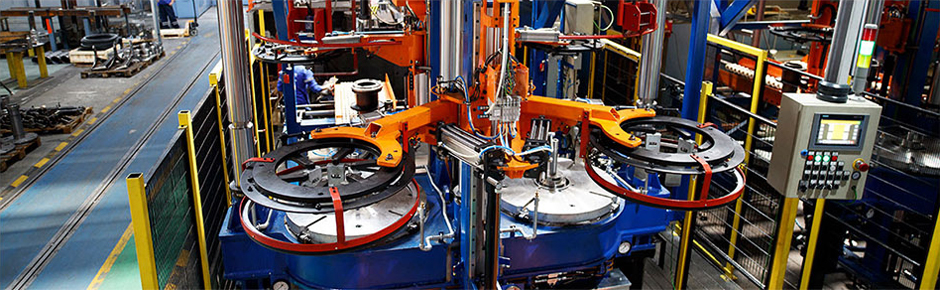

Tire manufacturing process is complicated, and mainly includes compounding and mixing, component manufacturing, assembly, curing and finishing steps. Out of these steps, curing is the process of applying pressure to the green tire in a mold to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber and other materials.

|

What are the challenges for tire curing process? |

|

Tire curing is critical throughout the tire-making process. Curing presses used to cure tires represent one of the largest capital investments for tire manufacturers. Tire manufacturers depend on curing presses for fast, reliable and repeatable performance.

|

|

|

Pipe systems on curing presses play a pivotal role on the curing process. The sources for high heat/pressure are transported through the pipeline and added to the curing process, including steam, hot water, Nitrogen or compressed air. Based on the media being conveyed, the pipelines can be generally divided into steam lines, hydraulic lines, vacuum lines and low pressure pneumatic lines, etc. Exposed to an environment with high temperature, high pressure, repeated vibration and shock, pipeline systems and control components (hoses, fitting and valves, etc) are particularly challenged to perform efficiently and safely at the same time. |

| High pressure |  |

|

Shock | ||

| High temperature |

Challenges |

Abrasion | |||

| Compatibility | Reliability |

|

How FITOK hoses can help? |

|

Therefore, the selection of control components should take account of a variety of factors, including ambient conditions, characteristics of the components and the media compatibility. Here we will focus on how we can help build a reliable pipeline system with optimized selection of hoses. |

For steam lines, high temperature and steam leakage are two major challenges. FITOK PS Series PTFE-lined, Stainless Steel Braided Hoses are rated for temperature up to 400℉ (204℃). Each hose is factory tested with pure water at 1.5 times maximum working pressure to ensure a leak-tight seal. With excellent dynamic flex life, the hose perform exceptionally well in flexing or vibrating applications.

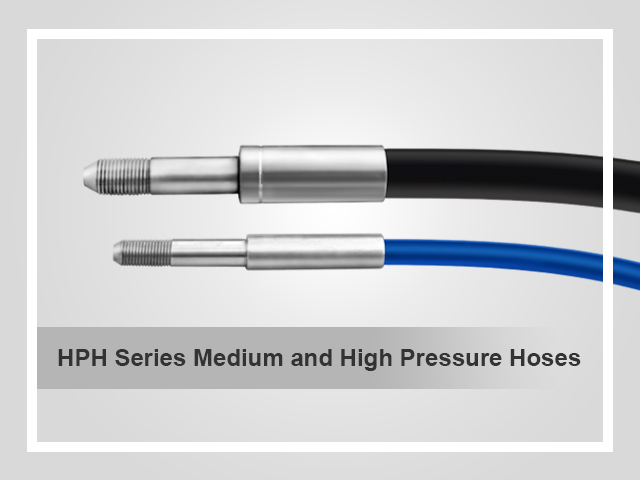

For hydraulic lines, pressure resistance is a priority concern. FITOK TH Series Thermoplastic Hoses can withstand pressure as high as 5000 psig (345 bar).

For low pressure pneumatic lines, in addition to quality and durability requirements, the hoses are also expected for ease of assembly and cost effectiveness. FITOK MP Series Multipurpose Push-on Hoses are weatherproof, abrasion withstanding and oil-resistant and spare your budget.

For vacuum lines, there is a high requirement for leak-tightness. FITOK MM Series Metal Flexible Hoses come with stainless steel convoluted core tube and are ideally used in vacuum environment with a helium leak rate of 1 x 10-9 mbar·l/s.

Specifications of FITOK Hoses

• Working temperature: -65℉ to 400℉ (-53℃ to 204℃)

Fittings crimped onto hose ends for leak-free connection

316 SS and Other

Alloy End

Connections

304 SS Overbraid

• Nominal hose size: 1/4" to 1"

Polyurethane Cover

• Resists oil, weather and abrasion

• Nominal hose size: 3/16" to 1"

Fiber Reinforcement

One High-strength Synthetic Yarn Laid

• For maximum strength and end connection retention

Synthetic Rubber Tube

• Highly oil-resistant

• Nominal hose size: 1/4" to 3/4"

Welded fitting-to-hose construction to ensure reliable seal

316 SS Core Tube

• Leak rate: 1 x 10-9 mbar·l/s

• Available for vacuum applications

316 SS Tube Fitting

304 SS Overbraid

• Nominal hose size: 1/4" to 2"

1. Anti-whip cable is available to prevent hoses from whipping around and causing serious injuries in the event of fitting blow-off or hose burst.

2. Spring guard is available to cover entire hose and protect against kinking and abrasion.

Except for hoses, the applications of curing press also involve tube fittings and ball valves, etc. For more information of hoses and other related products, please refer to the catalog or contact FITOK Group.

Related Articles:

.jpg)

.jpg)

Back

Back